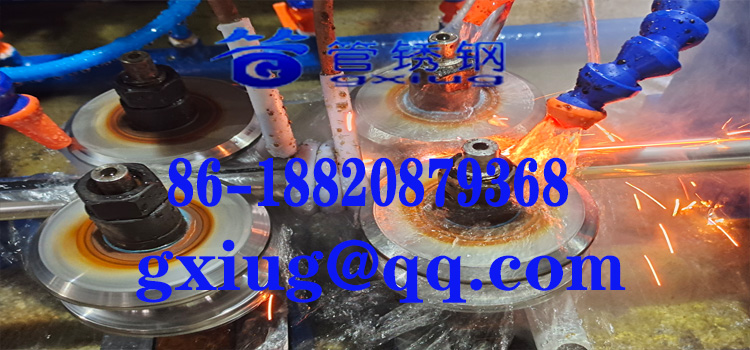

A few days ago, our company cooperated with the customer and under the careful guidance and assistance of our staff, our high frequency pipe welding equipment and pipe welding mould were successfully installed, and passed the site acceptance, and the pipe welding equipment was successfully put into production. As the saying goes, "When a machine rings, there are ten thousand ounces of gold." We look forward to better news from the customer in the next step.

I personally followed up the whole process of this high frequency pipe welding equipment and pipe welding mould. It can say that I have a clear understanding of every cable and screw of the equipment and witnessed the installation process of our pipe welding equipment and pipe welding mould with my own eyes. For the installation and debugging of some of the problems, some are also independently handled and solved by ourselves. This on-site installation experience made me more clear about the equipment situation, and provided me with a lot of experience in providing better service for customers and improving product performance in the future.

Next : Large diameter thin wall pipe welding mould process requirements are higher Back

Home

- [2020.05.16]Pipe making machine prod…

- [2020.05.16]The factory price of sta…

- [2021.07.09]Two patent applications …

- [2021.07.08]GXG technology passed IS…

- [2021.07.07]Installation of heavy th…

- [2020.05.14]This cold rolling mill i…

- [2020.08.24]70stainless steel decora…

- [2020.08.27]Drawings of welded pipe …

- [2025.02.26]Welded pipe machine and …

- [2021.03.05]Our first Iranian custom…

- [2025.01.13]fiber optic protection p…

- [2025.01.08]High frequency welding p…

- [2021.03.04]Installation of stainles…

- [2020.08.26]The 159caliber stainless…

- [2024.10.09]Second set of high-frequ…

- [2024.04.30]Our laser welding pipe m…

- [2020.08.26]159 stainless steel roun…

- [2023.12.20]Yemen precision high-fre…

- [2021.06.24]Congratulations on the s…

- [2023.06.01]Smooth debugging and pro…

Collection site

Collection site Feedback

Feedback Sitemap

Sitemap

+86-18820879368

+86-18820879368 gxiug@qq.com

gxiug@qq.com