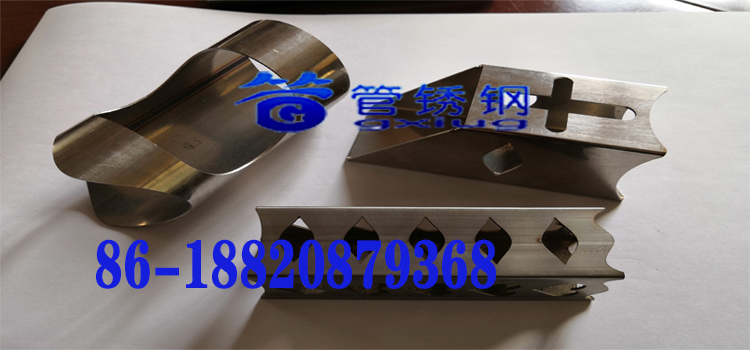

Since our company purchased the laser design last year, we have been able to process pipe diameters externally, not just the production of welded pipe machinery and welded pipe molds. In the laser cutting process, we are also seriously studying the advantages and disadvantages of laser drilling and traditional mechanical punching.

Laser tube cutting has the characteristics of faster speed, relatively accurate precision, and smoother nozzle. The traditional punching machine is relatively not so good, because it is stamped. And the nozzle is deformed a bit. In addition, for the speed, the mechanical punching can be designed to carry out multiple simultaneous, so the difference is not very big. It depends on the design.

Overall, I feel that laser cutting and hole drilling are still relatively good. If the financial pressure is low, it can be considered.Next : Different marking of welded pipe molds of different countries Back

Home

- [2021.05.25]What are the scrapers of…

- [2021.05.24]Electric control differe…

- [2021.04.07]Stainless steel decorati…

- [2021.05.24]Consideration of matchin…

- [2022.06.17]Internal scraper fixing …

- [2021.05.21]How to embody the abilit…

- [2021.04.06]Foshan welded pipe machi…

- [2022.06.07]The recent feedback from…

- [2021.05.20]What capabilities should…

- [2021.04.04]Integrated forming proce…

- [2020.04.16]Market share of large an…

- [2021.05.20]How to pack the stainles…

- [2021.05.19]Under the epidemic situa…

- [2021.05.19]High configuration desig…

- [2021.05.18]How to design keyway spe…

- [2021.05.17]Skyrocketing freight is …

- [2020.07.20]Those things between the…

- [2022.05.09]Analysis on advantages a…

- [2021.04.02]Design concept of welded…

- [2021.05.15]How to process the keywa…

Collection site

Collection site Feedback

Feedback Sitemap

Sitemap

+86-18820879368

+86-18820879368 gxiug@qq.com

gxiug@qq.com